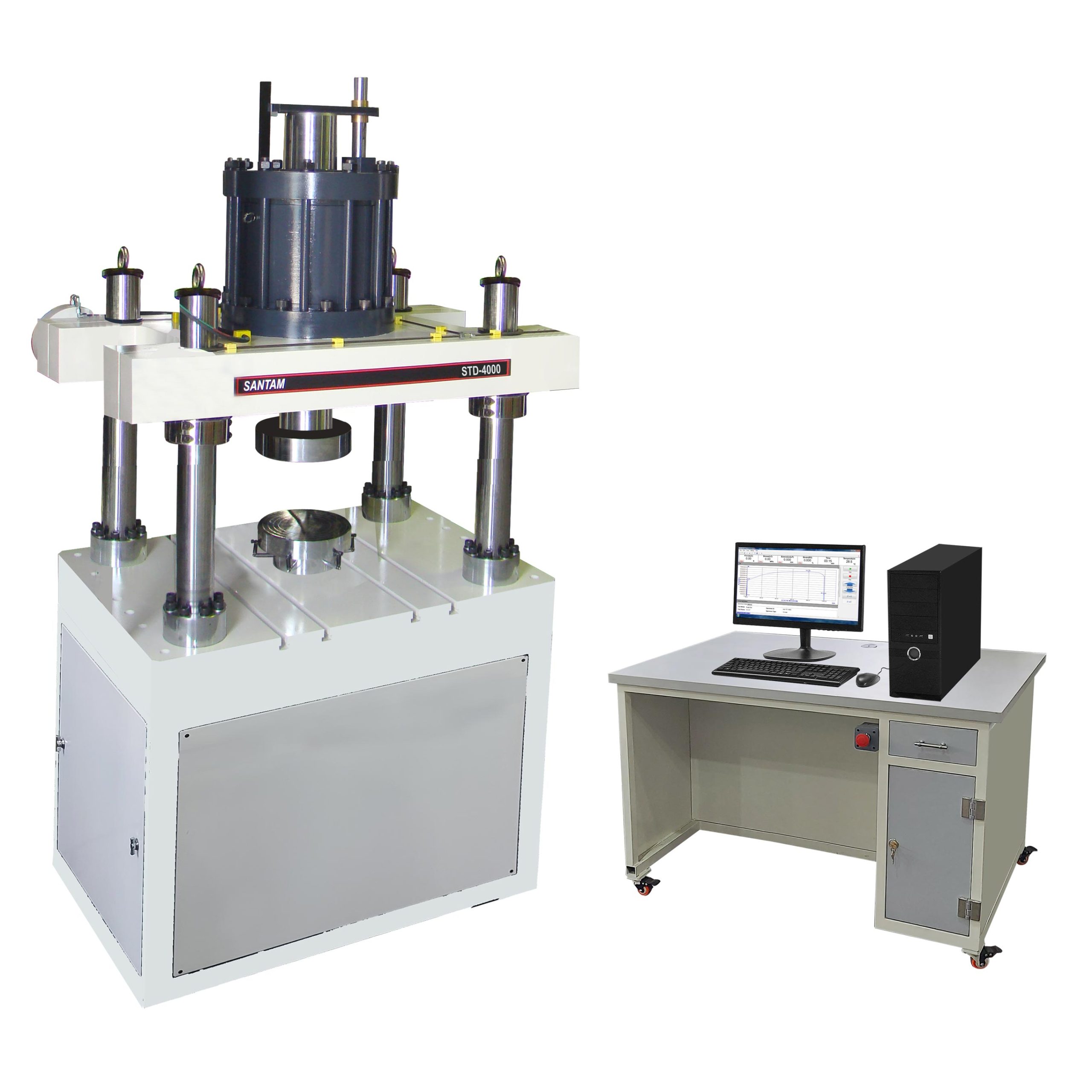

- Upset Compression Testing Machine or Cold Heading Test for testing steel wires

- Capacity: 400 t, 4000 kN

- Can perform Upset tests to investigate barreling effect compliant with ASTM E38M, ASTM A370, BS EN 10263

- Can perform CCS compression test on refractory bricks, cylindrical and cubic specimens in accordance with ASTM C133

- Operating Mechanism: electro-hydraulic actuator (EHA), with AC servo motor and driver, featuring a closed-loop control system

- Test capabilities: Compression and Cyclic tests using displacement control

- Reduced noise, low depreciation, and low power consumption (proportional to the applied load)

- Equipped with precise sensor for measuring crosshead displacement with 0.001 mm resolution; loading rate accurate control, specially at low speeds

- Fully computerized control via USB and RS-232 serial port with DSP-based processing (no PC type limitation)

- JADOO Controller software (Windows-compatible) for tensile, compression, cyclic and custom tests. Generates complete reports and multiple graphs such as: Force–Extension, Stress-Elongation, Force-Time, and Extension-Time

- Closed-loop speed control in real time, adjustable from 0.01 mm/min to 90 mm/min

- Capability to control speed with different methods (constant displacement rate, constant strain rate, constant true strain rate), and capable to define various tests with different loadings (force or stress, unilateral and incremental) when using JADOO software

- Equipped with digital non-contact electronic encoder mounted on the jack for full stroke measurement

- Compatible with various fixed and self-aligning platens

- Compact hydraulic unit integrated into the PC table; no auxiliary oil cooling required

- Portable control keyboard for convenient operation

A four-column rigid frame with a floor-standing design, offering ease of operation

STD-4000 is designed to perform compression tests on various steel or ceramic cross sections at very low speed in accordance with the relevant standards.

Upset Test (Cold Heading Test) is a method for evaluating the mechanical properties of materials, particularly for assessing wire performance within acceptance limits and its ability to withstand large and rapid plastic deformations without cracking or failing. In this test, a wire specimen of specified length and diameter is compressed between two parallel platens, which increases its diameter and decreases its length. The primary purpose is to verify that the wire can undergo significant deformation without defects. While tensile tests provide information on material strength and ductility (e.g., elongation), the upset test is specifically used to investigate compressive behavior and volume formability, which are critical for Cold Heading processes.

The tensile testing machine operates hydraulically and controls the load through an electro-hydraulic actuator (EHA). Displacement precision is enhanced by an AC servo motor and driver. Feedback from a non-contact displacement sensor mounted on the actuator enables highly precise testing at very low speeds (down to 0.01 mm/min).

Such performance is typically problematic and unattainable with conventional hydraulic systems. Unlike traditional setups, the EHA does not require continuous high-power operation, thereby reducing heat loss, power consumption, and mechanical wear – eliminating the need for an auxiliary oil cooling system. A further advantage, often highlighted by the operators, is the significantly reduced noise level compared to standard hydraulic system.

A pressure transducer is used to measure compressive force up to 400 t. The load frame is designed to allow easy mounting of various compression platens (unidirectional, incremental type).

Precise speed control is ensured by feedback from a high resolution (0.1 mm) non-contact electronic ruler, which stabilizes test speed across a wide actuator range. These capabilities allow operator to perform tests in accordance with ASTM A370, E8M, E9, E-209, C39M, C1609M, ISO6892-1/2, and ISO13314 standards.

High-resolution extensometers are available for precise strain measurement directly from the specimen rather than from the actuator. The system supports SANTAM’s STM Controller and JADOO Controller software. With these, the machine can record displacement through the extensometer attached to the specimen while simultaneously using the extensometer as feedback for closed-loop control under JADOO software, ensuring precise loading rate.

Upset Test Results Assessment

- After compression, the specimen is visually checked for cracks, breaks, or any surface or internal defects

- To pass the test, the wire specimen must show no visible cracks or breaks; the presence of any visible defect results in rejection

- The final shape of the wire is also critical – the deformation must be uniform and symmetric

If the Test Is Performed at High Speeds

- Material response may differ: some materials, especially at high strain rates, show brittle behavior. In such cases, a wire specimen that is accepted at lower speeds may crack at higher speeds and be mistakenly rejected

- Local heat generation: rapid plastic deformation can generate heat at localized points in the wire, temporarily affecting its mechanical properties.

- Inertia and non-uniform uniform force distribution: at very high speeds, inertia nay cause the comprehensive force to be unevenly distributed across the cross-section, leading to unreliable results

Recommended Speed (Direction)

- Standards generally do not specify an exact test speed (e.g., X mm/min) for Upset test. Instead, they emphasize on controlled and gradual load application

- The test speed should be low enough that plastic deformation occurs slowly and in a controlled manner, ensuring results accurately reflect the wire’s ductility. High-speed loading must be avoided, as it can lead to unreliable results or premature crack initiation. For this reason, the test is typically conducted under static and quasi-static conditions at relatively low speeds (e.g., few millimeters per minute).

STD-4000 is designed to perform compression tests on ferrous and non-ferrous metals using standard specimens. The machine supports compression platens and is widely used in QC laboratories, research centers, universities, and test service facilities. It is suitable for evaluating mechanical properties of a broad range of materials and for various applications, including:

- Steel wire production

- Research centers and universities

- Bolt, nut and metal fitting manufacturing

- Test service facilities

Upset Test (Cold Heading Test) is one of the specialized methods that provides comprehensive information about steel wires. It is a critical test for assessing the wire quality and applicability, particularly when the wires are intended to undergo severe plastic deformation (e.g., in bolt and nut manufacturing).

Why This Test Is Important for Steel Wires

- Evaluating Raw Material Quality: the test detects internal defects such as cracks, harmful impurities, segregation, or improper microstructure that may cause failure during subsequent processes (e.g., cold heading)

- Cold Heading Applications: components such as bolts, nuts, rivets, and pins are often produced by cold heading, where portions of the wire are plastically deformed. The Upset test simulates the wire ability to withstand this type of deformation

- Optimizing Wire Production Process: test results help the wire producers improve tensioning and heat treatment processes, enabling the manufacture of products with enhanced cold heading capability

- Reducing waste and cost: identifying defective wires early -before they enter the component production line- significantly reduces production waste and associated costs

JADOO Software Capabilities

- Specialized Windows-compatible software for defining and performing a wide range of tests, including creep, tensile, compression, bending, cyclic, step, relaxation tests

- Generates comprehensive reports with advanced features fully compliant with the catalog’s technical specifications

- Capable of applying advanced test speed (control rate) using various methods:

- Constant extension rate, constant strain rate, constant force rate, constant stress rate

- Constant true strain rate

- Constant true stress rate

- Capability to control and receive feedback from the extensometer under constant extension, constant strain rate, and constant true strain rate loading modes

- Capable of applying preloads with engineering parameters such as stress, force, extension, and …

- Cyclic test: capable of testing at various rates (force-extension, stress, and strain) and applying control limits without restrictions on the number of cycles

- Step test: capable of defining separate speeds at any control mode (force, extension, or strain) with customized set points

- Advanced creep test: conducted in three stages, with selective data acquisition in the third stage

- Relaxation test: conducted in three stages, with selective data acquisition in the third stage

- Capable of defining the second test speed based on various parameters

- Capable of determining the data acquisition rate in real-time for both short-term and long-term tests

- Equipped with PID controller coefficients for all control units (speed, extension, force, strain, and driver coefficient)

- Reporting: capable of defining any point on the graph, either by operator discretion or according to engineering definitions in relevant standards

- Capable of generating results for Elastic, Offset, Secant, and Tangent modulus at specified points

- Capable of plotting graphs for Force-Extension, Stress-Elongation, Force-Time, Time-Extension, Stress-Time, Elongation-Time, and Stress-Strain

- Supports simultaneous display and comparison of multiple graphs, with reporting of associated parameters

- Graphs and force values can be displayed in g, kg, N, kN, lb, Ton-Force, dN

- Allows input of different specimen dimensions in the software using multiple parameter options

You must be logged in to post a review.

قبل از ادامه دادن، مطمئن شوید که نام محصول را کپی کردهاید

برای دسترسی به این فرم لازم است به حساب کاربری خود در سایت سنتام وارد شوید

Reviews

There are no reviews yet.